Canada’s Instrumentation Leader Since 1946.

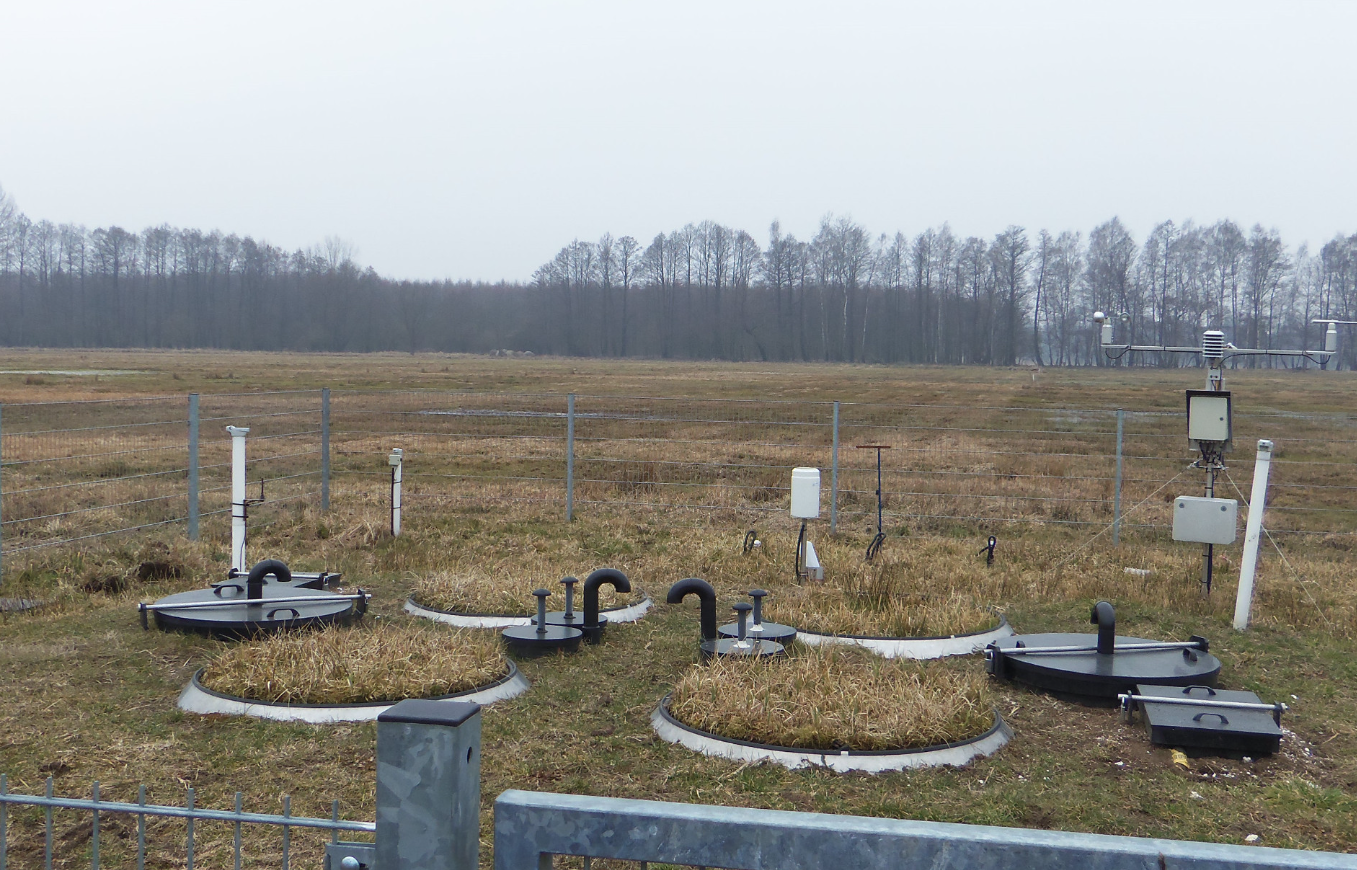

Our lysimeter stations in the patented containment design (patent no.: 199 07 463) are available to you as single or multiple stations. They comprise one or more lysimeter vessels with a diameter from 500 mm. The lysimeter depth is variable depending on the lysimeter diameter.

Our lysimeter stations in the patented containment design (patent no.: 199 07 463) are available to you as single or multiple stations. They comprise one or more lysimeter vessels with a diameter from 500 mm. The lysimeter depth is variable depending on the lysimeter diameter.

A lysimeter station consists of:

Your lysimeter station will be delivered by a freight forwarder and installed at your desired location by our trained UGT personnel. The installation of your lysimeter station includes:

In order to be able to ensure a continuous recording of the measurement data and thus to avoid possible data failures, we recommend a maintenance of the complete system twice a year. Our maintenance and service includes

If defects are found during maintenance that cannot be repaired on site or if devices have to be replaced, a separate quotation will be prepared in consultation with the customer.

Copyright - 2026 - Hoskin Scientific