Canada’s Instrumentation Leader Since 1946.

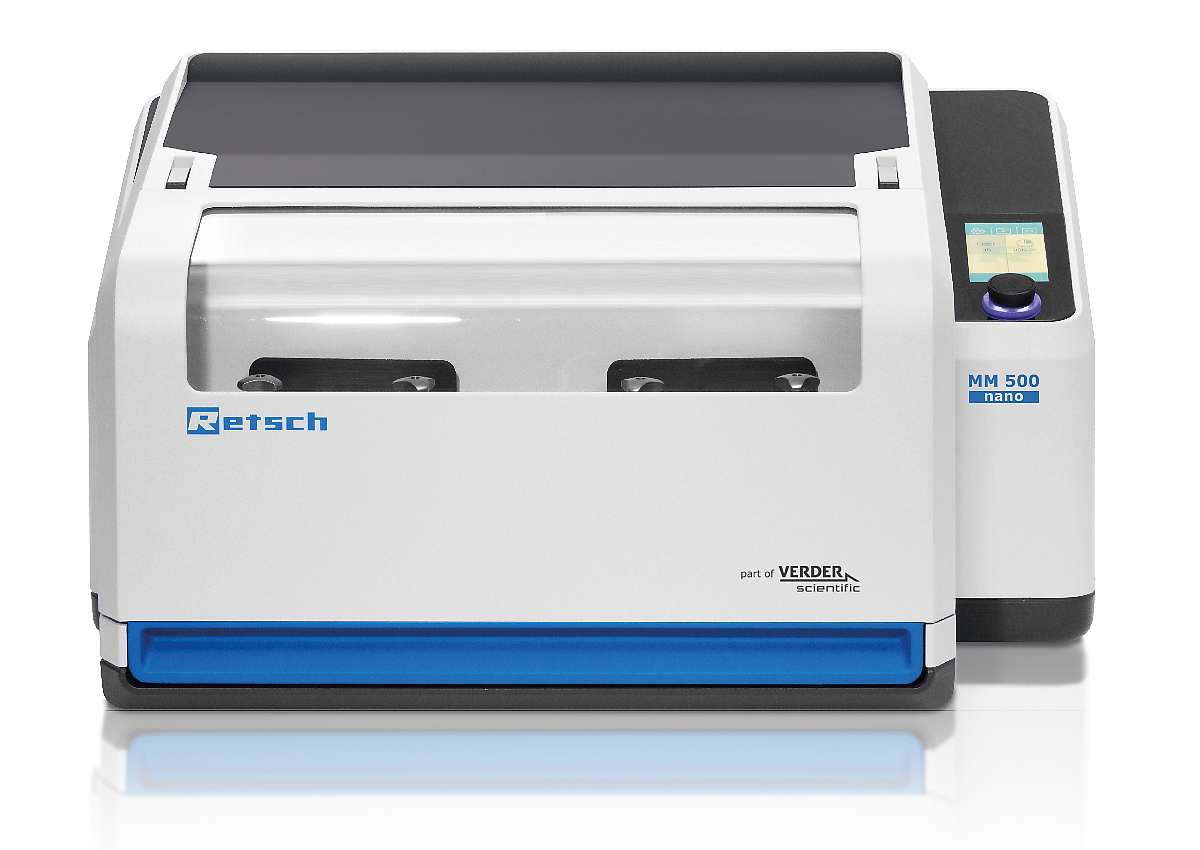

The mixer mill MM 500 nano is a compact, versatile bench-top unit which has been developed specially for dry, wet and cryogenic grinding of up to 2 x 45 ml sample material within seconds.

The mixer mill MM 500 nano is a compact, versatile bench-top unit which has been developed specially for dry, wet and cryogenic grinding of up to 2 x 45 ml sample material within seconds. With a maximum frequency of 35 Hz, it generates enough energy to produce particles in the nanometer range.

The robust high-performance drive makes the mill suitable for long-term grinding processes up to 99 hours and thus very interesting for research and mechanochemistry.

Hence, the MM 500 nano is a unique mixer mill in the market to provide a real alternative to grinding in a planetary ball mill – with more comfortable handling and less warming effects.

Result: You get your nano sample within the shortest time.

Simultaneous processing of several small samples is possible with the multi-cavity jars and an adapter for reaction vials. This is a typical requirement, for example, for pharmaceutical, chemical and biochemical applications. The small cavity jars provide new opportunities for mechanochemical research activities involving small amounts of chemicals. The cavities in the jars have an oval shape which ensures effective mixing. The pouring aids allow for safe sample handling.

The adapter accommodates up to 18 disposable reaction vials of 1.5 or 2.0 ml (e.g. Eppendorf vials) or nine 2.0 ml steel tubes. With its two grinding stations, the MM 500 nano mixer mill can now process up to 36 samples in one working run. 2.0 ml steel tubes should be used, if samples need to be frozen or heated, as polymeric reaction vessels cannot withstand mechanical load at extreme temperatures.

RETSCH mixer mills are true allrounders. They homogenize, for example: alloys, animal feed, bones, ceramics, chemical products, coal, coke, drugs, electronic scrap, glass, grains, hair, minerals, oil seeds, ores, paper, plant materials, plastics, sewage sludge, soils, straw, tablets, textiles, tissue, tobacco, waste samples, wood, wool, etc.

| Applications | mechanochemistry, mechanical alloying, size reduction, mixing, homogenization, cryogenic grinding |

| Field of application | agriculture, biology, chemistry / plastics, construction materials, engineering / electronics, environment / recycling, food, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | hard, medium-hard, soft, brittle, elastic, fibrous |

| Size reduction principle | impact, friction |

| Material feed size* | <= 10 mm |

| Final fineness* | ~ 0.1 µm |

| Batch size / feed quantity* | max. 2 x 45 ml |

| No. of grinding stations | 2 |

| Vibrational frequency | 3 – 35 Hz (180 – 2100 min-1) |

| Typical mean grinding time | 30 s – 2 min |

| Dry grinding | yes |

| Wet grinding | yes |

| Cryogenic grinding | yes |

| Cell disruption with reaction vials | no |

| Type of grinding jars | screw-lock jar with integrated safety closure devices, multi cavity jar, adapter for safe-lock reaction vials |

| Material of grinding tools | hardened steel, stainless steel, tungsten carbide, zirconium oxide |

| Grinding jar sizes | 10 ml / 25 ml / 50 ml / 80 ml / 125 ml |

| Setting of grinding time | digital, 10 s – 8 h |

| Total grinding time | 99 h |

| Storable SOPs | 12 |

| Number of storable cycle programs | 4 (with 99 repeats) |

| Electrical supply data | 100-120 V, 50/60 Hz; 200-230 V, 50/60Hz |

| Power connection | 1-phase |

| Protection code | IP 30 |

| Power consumption | 750 W |

| W x H x D closed | 690 x 375 x 585 mm |

| Net weight | ~ 60 kg |

| Standards | CE |

*depending on feed material and instrument configuration/settings

Copyright - 2026 - Hoskin Scientific