Geosense® VWS-2000 series vibrating wire surface strain mount gauges are designed for the long term monitoring of steel or concrete structures. Gauges may be attached to steel structures by arc welding or, using alternative end blocks, bonded or grouted into concrete. The strain gauge operates on the principle that a tensioned wire, when plucked, […]

Geosense® VWS-2000 series vibrating wire surface strain mount gauges are designed for the long term monitoring of steel or concrete structures. Gauges may be attached to steel structures by arc welding or, using alternative end blocks, bonded or grouted into concrete.

The strain gauge operates on the principle that a tensioned wire, when plucked, vibrates at its resonant frequency. The square of this frequency is proportional to the strain in the wire.

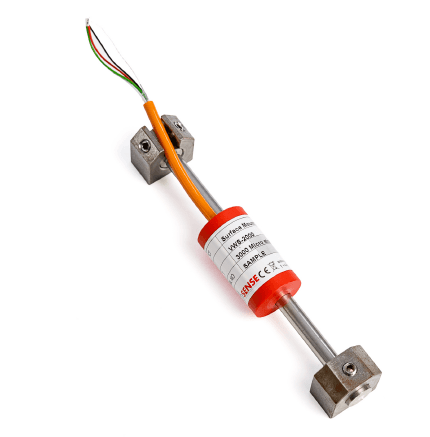

The gauge consists of two end blocks with a tensioned steel wire between them. The end blocks can be attached by either arc welding, bonding or groutable anchors to steel or concrete.

Around the wire is a magnetic coil which when pulsed by a vibrating readout or data logger interface plucks the wire and measures the resultant resonant frequency of vibration.

As the steel or concrete surface undergoes strain the end blocks will move relative to each other. The tension in the wire between the blocks will change accordingly thus altering the resonant frequency of the wire.

| Gauge length | 150, 89mm |

| Overall length | 156, 95mm |

| Resolution | 1 με, 1 με |

| Strain Range | 3000 με |

| Accuracy* | ±0.1 to ±0.5% FS |

| Non linearity | <0.5% FS |

| Temperature | -20°C to +80°C |

| Frequency range | 850-1550, 900-2000 |

| * 1 ±0.1% with individual calibration, ±0.5% FS with standard batch calibration | |