Canada’s Instrumentation Leader Since 1946.

Tanaka’s new Automatic Pour / Cloud / Freezing Point Tester mpc-6 is designed with “Simple, Reliable, and Robust” concepts. The mpc-6 requires a mere 4.5 mL sample and provides quick automatic determination of 3 key cold property measurements with high precision.

Tanaka’s new Automatic Pour / Cloud / Freezing Point Tester mpc-6 is designed with “Simple, Reliable, and Robust” concepts. The mpc-6 requires a mere 4.5 mL sample and provides quick automatic determination of 3 key cold property measurements with high precision.

INNOVATIVE

Tanaka’s original mini test methods which require much less

sample volume (4.5 mL) and short testing time compared to

conventional manual methods

SMALLEST FOOTPRINT

Very small width of 16 cm allows for most efficient use of bench space.

3-in-1

Test pour point, cloud point, and freezing point with just one instrument. Pour and cloud can be run simultaneously in a single run.

Eco-friendly

Equipped with CFC-free cooler achieving low noise, low vibration, and energy-saving. Sample temperature of -90℃ can be reached without external chiller.

Pour / Cloud/ Freezing Point Tester MPC Series

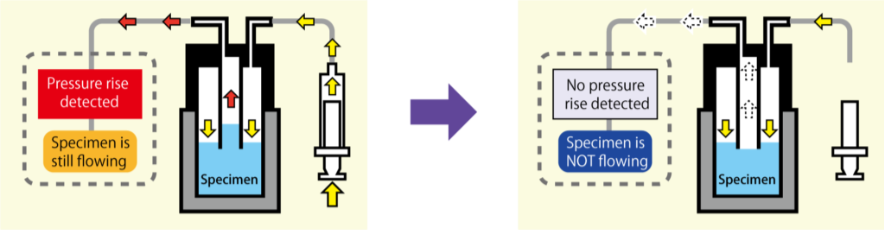

TANAKA’s MPC series has been designed for automatic determination of POUR POINT (PP), CLOUD POINT (CP) and FREEZING POINT (FZ) with small specimen size and shorter test cycle time while securing better test precision than the conventional manual methods. PP measurement is by “AIR PRESSURE METHOD” (ASTMD6749), and CP measurement is by “SMALL TEST JAR METHOD” (ASTM D7683).

The epoch-making automatic PP test method yields 1 ℃ test resolution, while the CP and FZ methods yields 0.1 ℃ resolution.

Principle of Pour Point Detection

| Specifications | |

| Compliant Methods | PP : ASTM D6749 CP : ASTM D7683 |

| Reference Methods | PP : ASTM D97, ISO 3016, JIS K 2269 CP : ASTM D2500, ISO 3015, JIS K 2269 FZ : ASTM D2386, ISO 3013, JIS K 2276 |

| Measuring Range | -90 ℃ to +51 ℃ (at room temperature of 25 ℃ ) |

| Temperature Range | -100 ℃ to +70 ℃ (at room temperature of 25 ℃) |

| Measurement Modes | PP/CP, PP, CP, FZ PP Pressure : L, H, VH, UH, SPE, Custom PP Intervals : 1.0 ℃, 2.5 ℃, 3.0 ℃, Custom CP Intervals : 0.1 ℃, 1.0 ℃ FZ Intervals : 0.1 ℃, 0.5 ℃ |

| Size (W x D x H) | 160 mm x 600 mm x 620 mm |

| Weight | 30 kg |

| Power Consumption | AC 100 V to 240 V 200 VA (max) 50 / 60 Hz |

Copyright - 2025 - Hoskin Scientific