Canada’s Instrumentation Leader Since 1946.

Geosense® VWS-2020 series vibrating wire strain gauges are designed primarily to measure strains on the surface of steel structures but may also be used on other types of material. The gauge consists of two end blocks with a tensioned steel wire between them. The end blocks are attached to stainless steel tabs which may […]

Geosense® VWS-2020 series vibrating wire strain gauges are designed primarily to measure strains on the surface of steel structures but may also be used on other types of material.

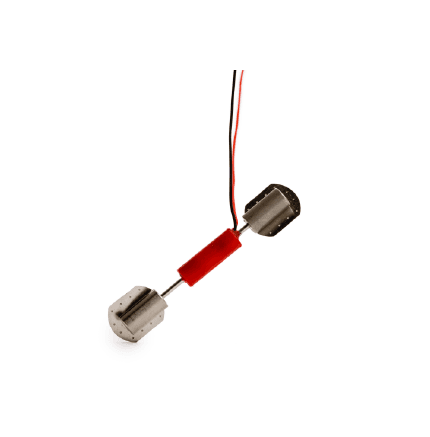

The gauge consists of two end blocks with a tensioned steel wire between them. The end blocks are attached to stainless steel tabs which may be attached to steel structures by spot welding or, using alternative end blocks, bonded or grouted.

Precision tensioning is carried out on site using a special tensioning jig and the gauge can be set for compression, tension or at mid point.

The strain gauge operates on the principle that a tensioned wire, when plucked, vibrates at its resonant frequency. The square of this frequency is proportional to the strain in the wire.

Around the wire is a magnetic coil which when pulsed by a vibrating wire readout or data logger interface plucks the wire and measures the resultant resonant frequency of vibration.

As the steel or other surface undergoes strain the end blocks will move relative to each other. The tension in the wire between the blocks will change accordingly thus altering the resonant frequency of the wire.

VWS-2020 strain gauges are available in two versions:

| Strain Range | 3000 με |

| Resolution | 0.4 με |

| Accuracy* | ±0.1% to ±0.5% FS |

| Non linearity | <0.5% FS |

| Temperature range | -20°C to +80°C |

| Gauge length | 49mm |

| Overall length | 65mm |

| *±0.1% with individual calibration, ±0.5% FS with standard batch calibration | |

Copyright - 2025 - Hoskin Scientific